Typically, rubber hose assemblies sold into the brewery market will consist of four to five major components; The inner Liner (tube), the Reinforcement, the Cover and the End Connections, however they are by no means limited to these. The components used in a rubber hose assembly are entirely dependent upon the requirements of the application and are decided on based on performance and suitability to ensure a fit for purpose solution is supplied.

The Hose Liner

The liner is the inner-most part of the hose and comes into direct contact with whatever media is being conveyed. It’s role is also to not only transport the media from point A to point B but also to protect the reinforcement and the cover from the media that is being conveyed. Throughout the hose industry companies will sell competing variations of brewery hose, many of which have different hose liners.

PVC – Whilst PVC is not used as a liner for rubber hoses it’s an important material to cover considering its wide use as a hose in beer production. We would never recommend PVC to convey beer due to the majority of PVC hose being cheap imports from outside Europe, manufactured in dirty environments and of low purity, usually resulting in it being toxic. PVC leaches into the media conveyed through it too so it’s possible the plastic taste/smell is then imparted into said product. PVC is also a petroleum derivative – fine for chemicals, fuels and non-drinkable water.

NBR – Is best for conveying dairy produce and fatty foods. It does not last long when alcohol is conveyed through it. We do not advise using Dairy hoses for beer or alcohol applications – it’s made for fatty foods, however many brewers are sold NBR dairy hoses as suitable for brewing with. The most common hoses we come across in the UK brewery market are NBR and EPDM.

EPDM – A versatile material with good chemical resistance. Performs okay with alcohols but will not last longer than 3 years before liner degradation begins to occur. For many years EPDM held the top spot for materials suitable for conveying beer or similar media, however that changed when Butyl was introduced as a higher-performance, longer lasting and superior alternative.

Butyl – A very high-performance synthetic rubber, odourless and taint-free, performs extremely well in conveying alcohols, even up to 96% purity. Not good with dairy products or fatty foods. Brewery hose assemblies with butyl liners can last up to seven years provided they are maintained accordingly. The inner liner of our Brewflex® hoses however are manufactured from a much higher grade of rubber – Butyl. As a material butyl has superior mechanical properties to that of both EPDM and NBR, briefly explained below.

Hose reinforcements

The reinforcement is the part of the hose which provides the strength to resist things such as vacuum and also flexibility to avoid kinging. A reinforcement inside a rubber brewery hose typically consists of either numerous layers of high strength synthetic plies and/or an internal wire spiral made from either steel or nylon. However, a reinforcement can also be classed as any additional component that provides support to the hose’ construction. Synthetic fibres increase the overall durability of the hose while steel wires provide vacuum and kink resistance and nylon wire helixes enable crush resistance.

Hose covers

The cover on a rubber beer hose assembly is designed to protect the reinforcement and /or the liner from the external environment. EPDM is the standard choice of material for covers used on rubber brewery hose assemblies as it acts has good resistance to abrasion, weathering and chemicals. The cover is essential to enable the product to work at pressure, stop elongational growth and improve bend radius and it acts as a protective cover giving mechanical strength to the whole hose assembly.

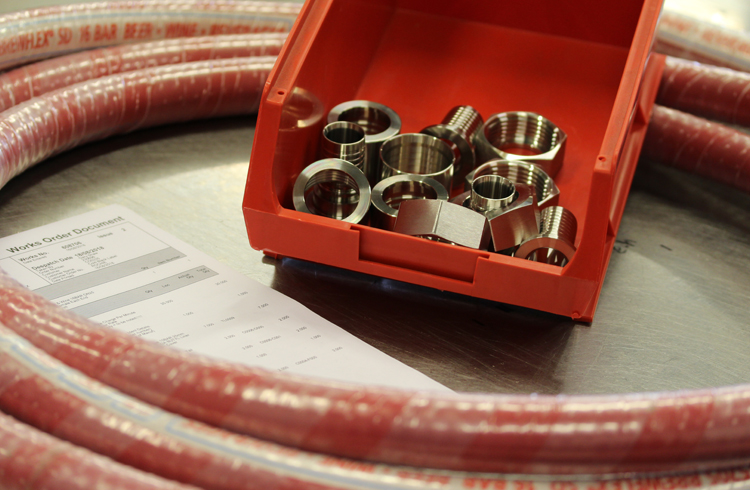

End connections

The end connections used also play a key role in the construction of a hose assembly as they are what connect the hose to the application. Flextech offer a wide range of 316L stainless steel couplings and fittings to suit the performance and hygiene requirements of brewery applications.

It is worth noting that there are two methods of attaching a fitting to a hose to form a complete assembly; worm drive clips and hygienic swaging.

Worm drives – fastened around the hose with the fitting in place. We do not advise this method as it leaves points of vulnerability in the hose where bacterial growth can occur. Over time as the hose is used the fitting can dislodge and even blow out requiring constant monitoring and tightening. Metal clips snag operator fingers – there is both a hygiene and health and safety risk here.

Hygienic swaging – A 316L stainless steel ferrule is crimped over the hose cover with a 316L fitting inside the hose. The two are secured together by the crimp and locking lip. Allows for smooth flow of product through hose, eliminates chance of bacterial growth between hose and fitting, simpler to handle, no snagging parts.